In today's competitive marketplace, businesses are constantly seeking innovative ways to distinguish their products and create memorable brand experiences. Custom paper box designs have emerged as a powerful tool for companies looking to enhance their packaging strategy while simultaneously reducing costs and environmental impact. These tailored packaging solutions offer far more than simple product protection, serving as silent brand ambassadors that communicate quality, values, and attention to detail to consumers at the critical point of purchase.

The strategic implementation of custom paper box designs extends beyond aesthetics, encompassing functional benefits that directly impact operational efficiency and customer satisfaction. Modern businesses recognize that packaging serves as the first physical touchpoint between their brand and consumers, making it essential to invest in solutions that reflect their commitment to quality and innovation. From luxury retail establishments to e-commerce giants, organizations across industries are leveraging customized packaging to create unboxing experiences that generate social media buzz and foster customer loyalty.

Brand Identity Enhancement Through Custom Packaging

Custom paper box designs serve as three-dimensional canvases for brand storytelling, allowing businesses to communicate their unique value propositions through visual elements, textures, and structural innovations. The strategic use of color palettes, typography, and imagery creates instant brand recognition while reinforcing key messaging that resonates with target audiences. Companies that invest in distinctive packaging designs often experience increased brand recall rates and stronger emotional connections with their customers.

Visual Consistency Across Product Lines

Maintaining visual consistency across diverse product ranges becomes achievable through standardized design elements incorporated into custom paper box designs. This approach ensures that regardless of product category or price point, customers immediately recognize the brand through consistent color schemes, logo placement, and design motifs. The resulting cohesive brand experience strengthens customer loyalty and simplifies inventory management for retailers who can easily identify and organize products from specific manufacturers.

Professional design teams work closely with businesses to develop comprehensive packaging guidelines that maintain brand integrity while allowing for product-specific variations. These guidelines typically include specifications for color usage, logo sizing, typography hierarchy, and graphic element placement, ensuring that every package reinforces the brand identity effectively. The investment in standardized design systems pays dividends through reduced design costs for future product launches and improved brand recognition in competitive retail environments.

Emotional Connection Through Tactile Experiences

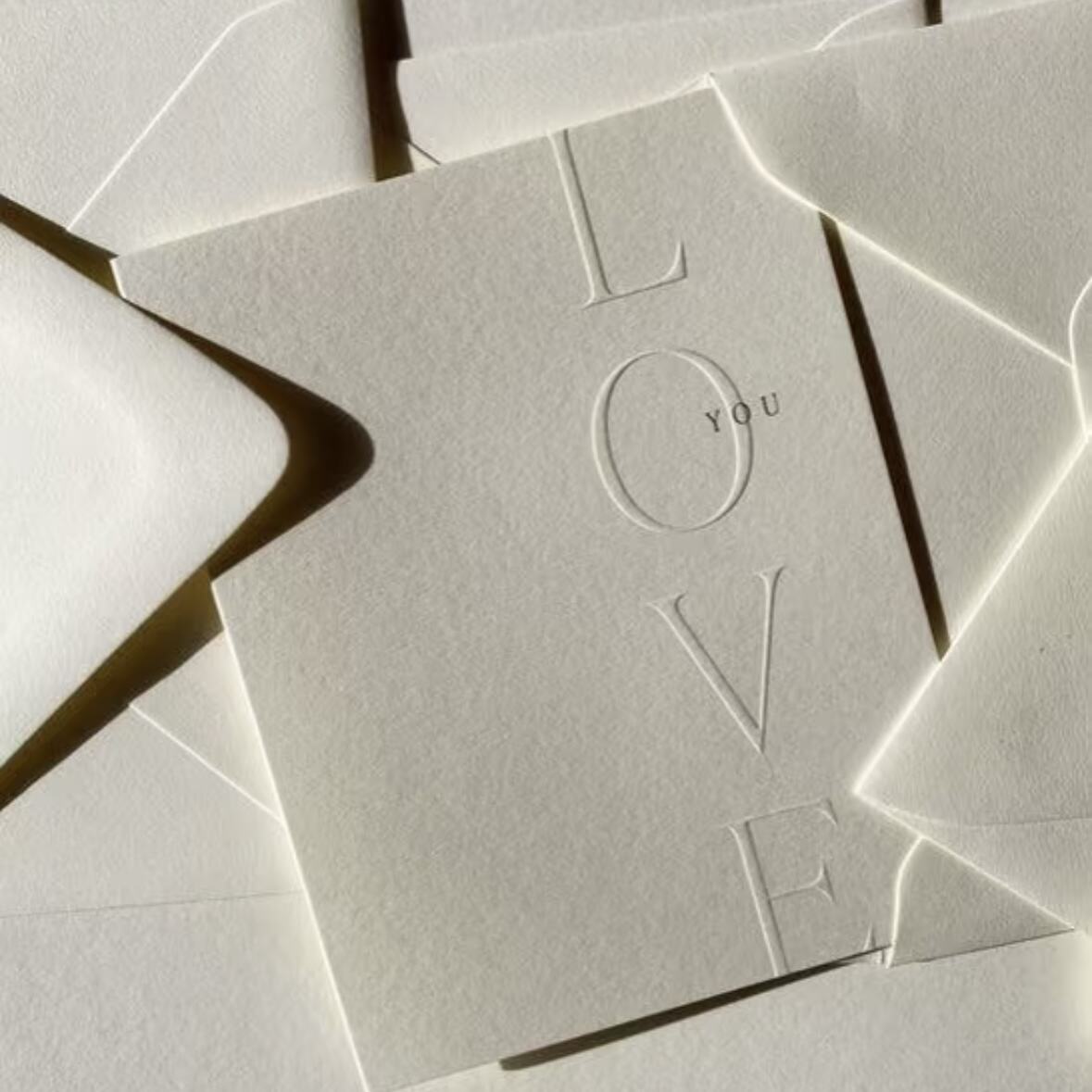

The physical interaction between consumers and custom paper box designs creates powerful emotional responses that influence purchasing decisions and brand perception. Premium finishes such as soft-touch coatings, embossed logos, or textured surfaces engage multiple senses, creating memorable experiences that digital marketing cannot replicate. Research indicates that consumers often associate tactile quality with product value, making sophisticated packaging an effective tool for premium positioning strategies.

Luxury brands particularly benefit from incorporating unique tactile elements into their packaging designs, as these features communicate exclusivity and craftsmanship. The weight, texture, and structural integrity of custom boxes contribute to the overall perception of product quality, influencing customer satisfaction and willingness to pay premium prices. Businesses that prioritize tactile experiences through their packaging often report higher customer retention rates and increased word-of-mouth referrals.

Operational Efficiency and Cost Optimization

Beyond aesthetic considerations, custom paper box designs offer significant operational advantages that contribute to improved efficiency and reduced total cost of ownership. Tailored packaging solutions optimize product protection during transportation while minimizing material waste and storage requirements. The strategic design of custom boxes can reduce shipping costs through improved space utilization and lighter weight materials, directly impacting profit margins for businesses with high-volume distribution needs.

Streamlined Production and Inventory Management

Custom paper box designs enable businesses to optimize their production workflows by standardizing packaging processes and reducing the need for multiple box sizes. This standardization simplifies inventory management, reduces storage space requirements, and minimizes the risk of packaging shortages during peak production periods. Manufacturing facilities benefit from streamlined packaging lines that require fewer changeovers and reduce the potential for operator errors.

The implementation of custom packaging systems often reveals opportunities for process improvements that extend beyond packaging operations. Companies frequently discover that optimized box dimensions reduce product handling time, improve warehouse organization, and simplify shipping calculations. These operational improvements contribute to faster order fulfillment times and reduced labor costs, providing competitive advantages in markets where delivery speed influences customer satisfaction.

Sustainable Material Selection and Waste Reduction

Modern custom paper box designs incorporate sustainable materials and manufacturing processes that align with corporate environmental responsibility initiatives. The ability to specify eco-friendly substrates, water-based inks, and recyclable coatings appeals to environmentally conscious consumers while reducing the company's ecological footprint. Sustainable packaging solutions often qualify for green certification programs that enhance brand reputation and open access to environmentally focused market segments.

The optimization of material usage through precise custom dimensions significantly reduces packaging waste while maintaining product protection standards. Right-sized packaging eliminates the need for excessive fill materials, reduces shipping volumes, and minimizes the environmental impact of transportation. Companies that prioritize sustainable packaging practices often discover cost savings that offset the initial investment in custom design development, creating long-term financial and environmental benefits.

Market Differentiation and Competitive Advantage

In saturated markets where product features and pricing become increasingly similar, custom paper box designs provide crucial differentiation opportunities that influence consumer choice. Distinctive packaging creates shelf appeal that captures attention in retail environments while communicating product benefits and brand values instantly. The visual impact of well-designed custom boxes can effectively compete with larger advertising budgets through strategic placement and compelling design execution.

Premium Positioning Through Design Excellence

Custom paper box designs enable businesses to position their products in premium market segments through sophisticated visual communications and high-quality production values. The investment in exceptional packaging design signals to consumers that the company prioritizes quality throughout the entire product experience, from manufacturing to final delivery. This positioning strategy often justifies higher price points and improves profit margins while attracting customers who value quality and attention to detail.

Luxury positioning through packaging requires careful consideration of design elements that communicate exclusivity without appearing ostentatious. Subtle design details such as foil stamping, embossed patterns, or unique structural features create sophistication while maintaining broad market appeal. The key to successful premium positioning lies in balancing distinctive design elements with practical functionality that enhances the overall product experience.

Innovation in Structural Design and Functionality

Advanced structural innovations in custom paper box designs provide opportunities for businesses to solve specific customer problems while creating unique selling propositions. Features such as easy-open mechanisms, resealable closures, or display-friendly designs add functional value that competitors using standard packaging cannot match. These innovations often become key selling points that sales teams can leverage during negotiations with retail buyers and distributors.

The development of innovative packaging structures requires collaboration between design teams, manufacturing partners, and end-users to ensure that creative concepts translate into practical solutions. Businesses that invest in structural innovation often discover additional applications for their custom designs, creating opportunities for licensing agreements or expansion into new market segments. The intellectual property value of unique packaging designs can become significant assets that contribute to overall company valuation.

Customer Experience and Unboxing Psychology

The psychological impact of unboxing experiences has gained increased recognition as businesses seek to create memorable interactions that extend beyond the initial purchase decision. Custom paper box designs play crucial roles in shaping customer emotions and expectations during product unveiling, influencing satisfaction levels and likelihood of repeat purchases. The strategic design of opening mechanisms, internal layouts, and progressive reveal sequences can transform routine unboxing into anticipated events that customers eagerly share on social media platforms.

Social Media Amplification Through Shareable Experiences

Well-executed custom paper box designs generate organic social media content as customers naturally document and share their unboxing experiences. The visual appeal of distinctive packaging creates photo-worthy moments that extend brand reach through authentic user-generated content. Businesses that design packaging with social sharing in mind often experience viral marketing effects that significantly amplify their advertising investments through genuine customer enthusiasm.

The design elements that contribute to shareability include photogenic color combinations, Instagram-friendly proportions, and surprise elements that create delightful discoveries during unboxing. Companies increasingly consider lighting conditions, background compatibility, and camera angles when developing custom packaging designs to ensure optimal social media presentation. The investment in share-worthy packaging often generates measurable returns through increased brand mentions, hashtag usage, and organic reach metrics.

Building Emotional Connections Through Sensory Engagement

Custom paper box designs that engage multiple senses create stronger emotional connections with customers, leading to increased brand loyalty and advocacy. The careful orchestration of visual, tactile, and even auditory elements during unboxing creates memorable experiences that customers associate with positive emotions. These emotional connections often translate into increased customer lifetime value and reduced acquisition costs for replacement customers.

Sensory engagement strategies include the use of premium materials that feel substantial and luxurious, subtle fragrances incorporated into packaging materials, and satisfying opening mechanisms that provide tactile feedback. The psychological principle of anticipation plays a crucial role in unboxing design, with well-designed packages building excitement through progressive revelation of contents. Businesses that master the psychology of unboxing often discover that packaging becomes a significant factor in customer retention and referral generation.

Implementation Strategy and Best Practices

Successful implementation of custom paper box designs requires strategic planning that considers budget constraints, timeline requirements, and scalability needs. Businesses must evaluate their existing packaging operations, identify improvement opportunities, and develop implementation roadmaps that minimize disruption to ongoing operations. The transition to custom packaging often reveals insights about product positioning, customer preferences, and operational efficiencies that inform broader business strategy decisions.

Vendor Selection and Partnership Development

The selection of packaging partners significantly influences the success of custom paper box design implementations, requiring careful evaluation of capabilities, capacity, and cultural alignment. Ideal partners demonstrate expertise in both creative design and manufacturing excellence while maintaining flexibility to accommodate changing business needs. Long-term partnerships often yield better results than transactional relationships, as established vendors develop deeper understanding of brand requirements and operational preferences.

Partnership evaluation criteria should include manufacturing capabilities, quality control systems, sustainability practices, and geographic distribution of production facilities. The ability to provide design consultation, prototype development, and scalable production solutions distinguishes premium packaging partners from commodity suppliers. Businesses that invest time in thorough vendor selection processes often experience smoother implementations and better long-term outcomes.

Prototype Development and Testing Protocols

Comprehensive prototype development ensures that custom paper box designs meet functional requirements while achieving desired aesthetic goals. Testing protocols should evaluate structural integrity, manufacturing consistency, shipping durability, and end-user experience across diverse conditions and usage scenarios. The investment in thorough prototyping prevents costly production issues and ensures that final products meet quality expectations.

Effective testing protocols include drop tests, compression tests, humidity resistance evaluations, and real-world shipping simulations that identify potential failure points before mass production begins. Customer focus groups provide valuable feedback on usability, aesthetic appeal, and perceived value that inform final design refinements. The iterative nature of prototype development allows for continuous improvement while maintaining project timelines and budget constraints.

FAQ

What factors should businesses consider when determining the optimal budget for custom paper box designs

Budget determination for custom paper box designs depends on several key factors including production volume, design complexity, material specifications, and desired functionality. Businesses should evaluate the total cost of ownership, which includes design development, tooling costs, per-unit manufacturing expenses, and potential savings from operational efficiencies. Generally, higher volume orders achieve lower per-unit costs, while premium materials and complex structural designs increase overall investment requirements. Companies should also consider the marketing value of distinctive packaging when calculating return on investment, as effective custom designs often generate brand awareness equivalent to significant advertising expenditures.

How long does the typical development timeline require for custom paper box design projects

Development timelines for custom paper box designs typically range from 4-12 weeks depending on project complexity, approval processes, and production requirements. The initial design phase usually requires 1-3 weeks for concept development and client review, followed by 1-2 weeks for structural engineering and technical specifications. Prototype production and testing add another 2-3 weeks, while final production setup and initial manufacturing runs require an additional 2-4 weeks. Businesses planning seasonal launches or time-sensitive product introductions should begin custom packaging development at least 3-4 months in advance to accommodate potential revisions and ensure adequate inventory availability.

What sustainable material options are available for environmentally conscious custom paper box designs

Sustainable material options for custom paper box designs include recycled cardboard substrates, FSC-certified virgin fibers, agricultural waste-based papers, and biodegradable coating alternatives. Water-based inks and adhesives eliminate harmful solvents while maintaining print quality and structural integrity. Many manufacturers now offer post-consumer recycled content options that achieve up to 90% recycled material composition without compromising structural performance. Additionally, innovative bio-based coatings derived from plant materials provide moisture resistance and enhanced durability while remaining fully compostable in industrial facilities.

How can businesses measure the effectiveness and return on investment of custom paper box design implementations

Measuring the effectiveness of custom paper box designs requires tracking multiple metrics including brand recognition improvements, customer satisfaction scores, social media engagement rates, and sales performance comparisons. Businesses should establish baseline measurements before implementation and monitor changes in key performance indicators such as unboxing video shares, customer retention rates, and premium pricing acceptance. Operational metrics like packaging waste reduction, shipping cost savings, and inventory turn rates provide quantifiable ROI calculations. Advanced analytics can track customer journey impacts, including how packaging influences repeat purchase behavior and referral generation, providing comprehensive insights into the total value created by custom packaging investments.

Table of Contents

- Brand Identity Enhancement Through Custom Packaging

- Operational Efficiency and Cost Optimization

- Market Differentiation and Competitive Advantage

- Customer Experience and Unboxing Psychology

- Implementation Strategy and Best Practices

-

FAQ

- What factors should businesses consider when determining the optimal budget for custom paper box designs

- How long does the typical development timeline require for custom paper box design projects

- What sustainable material options are available for environmentally conscious custom paper box designs

- How can businesses measure the effectiveness and return on investment of custom paper box design implementations